Our Comprehensive Infrared Inspections Are Non-Invasive and Non-Destructive

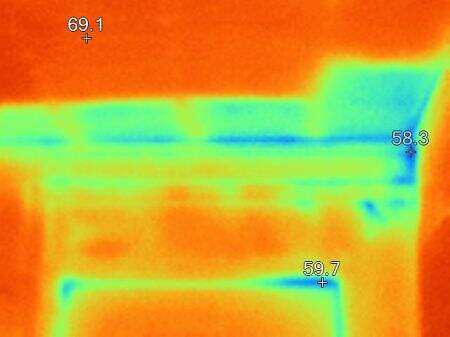

Infrared cameras provide a non-invasive and non-destructive means of looking at a buildings integrity making them useful for a number of applications. IR cameras allow the operator to see things not always visible to the naked eye. IR cameras are an extremely powerful tool when used properly, that's why Myers Electric & Infrared employs a certified thermographer trained in how to properly use an infrared camera and interpret thermal images correctly.

Examples of a few applications where an infrared inspection can be used:

Electrical Systems

- loose or poor connections

- overloaded circuit breakers or wiring

- overheated electric motors

Mechanical Systems

- failing or faulty bearings

- issue with rotating equipment such as improper alignment or overloaded equipment

- problems with, or locating in-floor heating systems

Building/Equipment Envelope

- missing or poor insulation in buildings

- industrial refractory/insulation inspections

- locating leaks in roofs

Agriculture

- rotating farm equipment including electric motors, bearings, and harvesting equipment

- grain piles and bunkers

Preventative Maintenance

Infrared inspections are an extremely important part of any PSM program. A properly done IR inspection can detect issues with equipment early, preventing unexpected down time, major equipment damage, and in some cases personal injury.

Contact us today to see what an infrared inspection can do for you!